Equipment: The Basic System

WHAT THE ENGRAVING MACHINE DOES

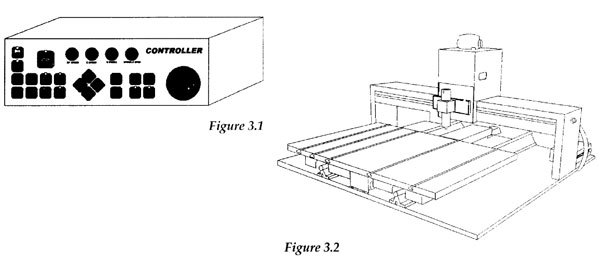

The brain of the computerized system is the engraving controller (Figure 3.1). It takes the information from your layout software (located or resident in your PC) and translates it into a form your engraving machine can understand. The controller allows manipulation of all of the important factors including the home position (your starting point), speed, depth, if and when to pause and other important features. A high-quality engraving controller effects the number of options, variations and possible actions your engraver table can perform and can affect the accuracy of your engraving system.

The engraving machine or table (Figure 3.2) receives information from the controller on how to move the cutting tool into and around your engraving job. The engraver utilizes this information and uses motors to move the X- and Y-axis as well as the spindle. While very accurate, the engraving machine can only follow the instructions given to it by the engraving controller. Combined with a good controller the results can be very impressive. It's important to remember that every engraving system is made up of the PC whether an integral part of the system or separate, the controller, and the table. All three components must exist in some form regardless of how they are constructed. The engraving table must get its instructions from some electronics that "drive" the table's stepper motors. This information is supplied by the software program associated with the engraving operation and is interpreted by the control unit.

OPEN-ARCHITECTURE VS. PROPRIETARY SYSTEMS

Before we can discuss the practical applications for this technology, a definition of open-architecture is important. Simply put, open-architecture is the ability to link hardware, software, and other output devices in a multitude of combinations. Given the flexibility of using this technology, there are several compelling reasons why an engraving shop should at least investigate an open-architecture system. You may not be able to distinguish between a "true" open system and one that is simply "compatible" with other hardware or software programs. Here are some of the clues to determine what you may have and where to go from here if you are in the market for an upgrade or considering a new system.

YOUR PRESENT HARDWARE

If you already own an older engraving system you may have a closed "proprietary" design. "Proprietary" simply means that the individual hardware components were designed, made, and sold by one manufacturer and usually incorporated with one engraving software program. Often these are completely self-contained units that can easily be transported and quickly set-up. The system has an on-board electronics package that includes the system's CPU (central processing unit) or "brains." The software included may be tailored to that specific hardware model and has limited software features.

The advantage of this type of design is that you can plug it in and you're basically ready to engrave. The disadvantage is, because of the closed architecture nature of the system, you cannot easily take advantage of versatile third-party software programs or today's bigger computing power. If you cannot easily upgrade the CPU of the electronics or you cannot easily import files from other software programs, you probably have a closed system. If your system uses cartridges to import fonts or logos, you definitely have a closed system. Chances are that the manufacturer has very few options to help you upgrade to more current technology, but some portions of the hardware system may be salvageable. You will need to weigh the price for upgrading against the purchase of newer technology given your future business needs.

Even if you have a more recent PC-based design, it may still be proprietary in design. If you cannot select different industry software programs as the primary means of driving your system, you probably have a closed-architecture electronics package. One of the telltale signs is the inability to directly drive the system from third-party packages even though you can import software files into your system software for further manipulation. Other signs are complicated workarounds to convert files or import and export tasks and extra steps necessary to get a clip-art or job into your primary software for engraving.

A true open-architecture system allows the user to select almost any desired software programs to drive the engraving system directly. There is no need to import files or go through any extra conversions to engrave a job. Today's software has become increasingly sophisticated, and PC computing power changes daily. A closed system would not allow you to take advantage of these improvements. To be open, the hardware must be compatible with many software programs. This means that you can use programs such as CorelDRAW™, ScanVec's CasMate-Pro™ or Inspire, EnRoute™, CadLink's EngraveLab-Pro™, Amiable Technologies' FlexiENGRAVE™, AutoCAD and more. If you've not investigated these packages, you should. They represent strong graphics oriented programs that give the user incredible design flexibility.

WHY CONSIDER AN OPEN SYSTEM?

First, the old (but faithful) system you currently have will almost certainly need to be replaced someday. Parts and support will become more difficult to find, and the on-going costs to repair the system will become prohibitive. At that time, the hardware and software advances will be such that a leap forward will be mandatory. You will probably have a choice at that time of purchasing a closed (proprietary) system or selecting an open-architecture solution. By investigating options now, you may decide that now is the time to adopt a cost-effective portion of the technology that will allow you to keep up without making a complete system investment. You may only need to upgrade your existing electronics or a portion of your engraving table to give you the flexibility of running these third-party options. This could be a cost-effective solution to make your shop more productive today without spending precious dollars on a complete new system.

Second, and more important than any other factor, is that with open-architecture technology, you have a software choice. This choice will allow you to meet your business needs today and tomorrow. If you decide to take your business in another direction, or feel that the addition of other output devices is warranted, then adding a graphics package with the ability to change and grow will be possible. These programs allow you to enter into business opportunities in sign-making, screen-printing, vinyl-cutting, industrial engraving and 3-D carving applications.

PROPRIETARY DESIGNS

If you consider a closed or proprietary design, it should be done on the basis of your specific engraving application and future plans. If you intend on providing only limited applications with little need for custom logos or clip art, then a closed system may be appropriate. These systems will have more simplistic software that will be easy to use for the limited applications it was designed for. However, these systems may not allow much room for growth, so beware. Most of these systems may seem less expensive in the beginning, but what if you find yourself in the position of needing new hardware before you have even recovered your initial investment? It is important to note that self-contained proprietary systems may be less expensive, and a considerable cost savings may be had if you are just testing the engraving waters.

USED EQUIPMENT

Purchasing second hand equipment may be an excellent way to save money. If you are making your first investment in engraving or adding capacity to your existing shop, purchasing used equipment can be a good decision. Other businesses that have failed, merged or outgrown their existing equipment are often good sources. However, just as with purchasing a used car, there are pitfalls. If you do not know much about the system you are buying or you know even less about the person selling you the equipment, you may want to avoid this approach altogether.

There is a tremendous range of used equipment available on the market. You can find listings under the classified section of most of the industry trade publications. Do your homework before making a buying decision. If the deal looks too good to be true, it probably is.

Some things to consider when buying used equipment:

- How will I get training? Will I get training from the owner? If purchased long distance, none may be available.

- What condition is the equipment in and does it reflect the current revisions? The previous owner may not have kept the equipment in good repair and you may be faced with a big bill to get the equipment up to snuff.

- Will I get a complete system when I buy it? Again, unless you have direct knowledge of the hardware and can ask all of the right questions, you may not get a critical piece. If the system is open architecture, the software may not be included in the price.

- Does the manufacturer still support the design? The manufacturer considers many older systems obsolete and spare parts are not readily available.

- Is there a warranty available from the manufacturer or can a service plan be purchased? If the equipment is relatively new, perhaps a salesmen's demonstration model, part of the original equipment warranty may be in effect. The manufacturer may charge a small fee to transfer the warranty to the new owner or may request that the equipment come to a service location for evaluation prior to honoring the remaining warranty. You may also be able to purchase an extended service plan to protect your investment.

Buying a used system may be a good idea if you have a dedicated need or limited budget. Be sure to investigate the seller and the equipment thoroughly before making a decision. New equipment may give you the best performance and peace of mind, and in the long run, may be the best buying decision you can make.

The Engravers' Bible © 1999 by Rich Zydonik/National Business Media, Inc. Printed and Bound in the United States of America. All rights reserved. No part of this self-study manual may be reproduced in any form without permission in writing from the author/publisher. Additional legal, financial and professional management advice and/or assistance are encouraged.