Engraving: Nosecones

Once the correct cutter and spindle have been determined, a proper nosecone for the job must be selected. The nosecone is the plastic or metal part of the engraving spindle that will touch or ride over the material surface while engraving. You may ask, “Why use a nosecone at all?" The reason is simple: Of all the different methods of cutting there are to choose from, using a nosecone will produce an engraver's most desired result - a consistent depth of cut. Due to the shape of the cutter, deeper cuts will result in wider letters and shallow cuts will result in narrow letters. If this occurs in the same job the appearance will be unsatisfactory.

Engraving, unlike machining operations, takes advantage of the use of a nosecone to control the depth of cut. Several factors can negatively influence the depth of the finished engraving and the resulting letter quality:

- Plastic engraving stock may have variances in the cap layer thickness resulting in voids in the cut.

- The engraving system table may not have a level surface causing uneven cutting without the use of the nosecone riding on the surface.

- Mechanical tolerance in the engraving system can cause various depths of cut.

- Without a nosecone to regulate depth, multiline fonts cut with a wide cutter can be deeper in the center of the character as the cutter moves toward the middle of the character.

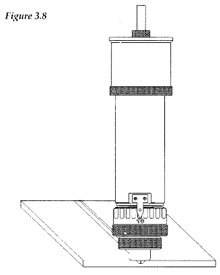

Figure 3.8 illustrates the part the nosecone plays in the engraving process.

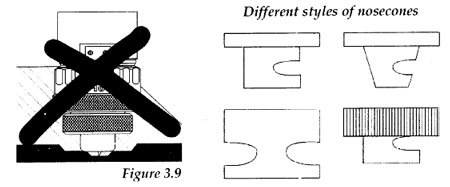

To control the depth, engravers have a choice between two basic styles of nosecone: screw-on or drop-in. Each style could be made of either plastic or metal.

Metal nosecones of either the screw-on or drop-in variety are very durable and often are included as standard equipment with many engraving systems. They're good on most plastics and other hard surfaces.

Plastic nosecones are preferred when marring of the material surface is a concern. Usually these are confined to use with plastic engraving stock that has a satin or brushed finish.

Finally, remember when selecting the nosecone to pick one with a large enough diameter and correct shape for the job. Selecting a nosecone with a large enough diameter is important so that it does not fall into the previously engraved area (Figure 3.9). You can see the depth control problem you would have if the nosecone dropped into the existing engraved letter. This is generally only an issue if you are doing large letters or signs where the background area must be routed out.

The size of the diameter of the nosecone opening is also directly related to the shank size of your cutter. You will need to select a nosecone that allows the shank of the cutter to protrude beyond the nosecone. Special highly tapered nosecones are available for tight to reach engraving areas. You will need to be sure that the cutter can properly rotate within the nosecone without rubbing the interior nosecone surface. Damage can occur to the nosecone and cutter if the clearance is not sufficient.

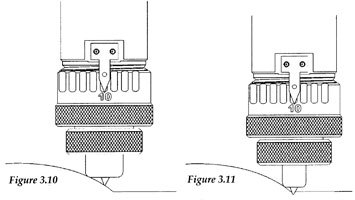

When working with convex or concave surfaces, a large nosecone on a slightly curved surface (Figure 3.10) will contact the object at some point and probably scratch the surface. A narrow, tapered nose (Figure 3.11) will more closely follow the contour and travel without interference, giving you the expected result.

The Engravers' Bible © 1999 by Rich Zydonik/National Business Media, Inc. Printed and Bound in the United States of America. All rights reserved. No part of this self-study manual may be reproduced in any form without permission in writing from the author/publisher. Additional legal, financial and professional management advice and/or assistance are encouraged.