Basic Engraving Techniques: Non-Nose Ride Engraving

Fundamentally the same as nose riding, non-nose riding engraving is simply cutting without the use of the nosecone on the material surface. There are several reasons why we might choose to do non-nose riding engraving. It's important to recognize when this may be the best solution to solve an engraving problem.

Metal nosecones by their nature may rub the material surface. When we have an application such as a highly polished piece of material, we may want to take the nose cone completely out of the process. Since this procedure has drawbacks, it may be best to eliminate the effects of nose rub through all the other methods first. Consistent depth control is the most critical issue when non-nose riding so other steps to solve the problem should be explored first when possible.

- Select a different material for the job if possible. If the material is metal, you may be able to apply a thin gage material to the top surface and still nose ride over the area to keep a controlled depth. This adds cost, an extra step and maybe more clean up. It may be difficult if the material that needs to be cut requires lubrication. The lubrication may get under the first surface and lift the waste material during engraving. Test the adhesive first if possible.

- Reduce nosecone pressure by backing off on the air pressure if you operate an air-driven z-axis system. If you system has a motorized z-axis, control the z-stroke via your mechanical settings or software. In the case of our polished metal plate, we may be able to nose ride and then perform some finishing work to re-polish the surface providing that the rub and scratches are minimal.

- Leave the protective plastic coating on the sheet stock when engraving plastic such as engraving stock, acrylics and Plexiglas. Not a favored method but effective in most cases.

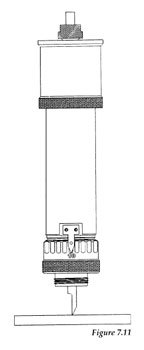

If these methods are not easily achievable, then non-nose riding engraving is probably the best solution. (See Figure 7.11) You will need to take a few steps to determine if this process will work with your engraving system and for the particular application. Start by making sure you have the right set up by answering these questions:

- Is my system capable of having a Z-axis stop at a controlled point (for air-driven systems) or is the depth controlled by software for motorized Z-axis systems? You need to remember that we are going to have a tool hanging completely free over our work. The plunge depth must be controlled by some means to avoid cutting do deeply.

- Is my table flat enough for the process or can I level it?

- Will slight variations in cutting depth affect the finished look and will the customer accept these variations? If the work is a logo only (no text) you may get by. If there is text involved, the change in depth will change the stroke width and the resulting characters will be unacceptable. If you are fortunate, you may have a very flat table and this may not be an issue for you.

Unfortunately, the flatness of the engraving table will affect the engraving appearance. There is little that can be done to help this problem. Leveling a sub-surface may be the only answer. You can find this procedure in Chapter 7, which deals with Advanced Engraving Techniques.

TECHNIQUE

Place you cutter into you top or bottom load spindle and leave enough cutter length protruding below the nosecone to reach the maximum depth you need to cut. Notice I said below the nosecone. I recommend leaving the nosecone on the spindle as a fail-safe stop against an improper set-up. If you accidentally put a wrong value into the depth field while setting the depth of cut in the software, the nose would stop the Z-axis travel. Without taking this precaution, you could plunge deeper into the material than planned. This way, you stop the tool from breaking or adding additional holes in your engraving bed.

If you are cutting plastics or acrylics you may be able to get some limited performance from your vacuum system. Use the vacuum nose as the "fail-safe" stop. Leave the nose a few thousands of an inch above the deepest cutter setting. If the chips are small you may get some pick-up.

Next, check the flatness of your engraving table. If you are unsure, run a test plate first (same size as the required job). Try a simple border with an X through the center of the plate. Hopefully the depth over the entire area is within tolerable amounts. If not, you may want to consider adding a sacrificial surface to the table. This will bring the overall flatness tolerance within acceptable levels. See Chapter 9.

Lock the Z-axis mechanism to remove any float. Since no nosecone is involved and we are not resting against the material surface, we can expect some resistance when the cutter enters the material. This "back pressure" will cause the cutter to bounce along the material. In very hard materials this will at a minimum break the cutter. It will also produce a very ragged and poor quality cut that will be unacceptable.

All other aspects of the job remain the same so follow your normal set-up procedures.

The Engravers' Bible © 1999 by Rich Zydonik/National Business Media, Inc. Printed and Bound in the United States of America. All rights reserved. No part of this self-study manual may be reproduced in any form without permission in writing from the author/publisher. Additional legal, financial and professional management advice and/or assistance are encouraged.